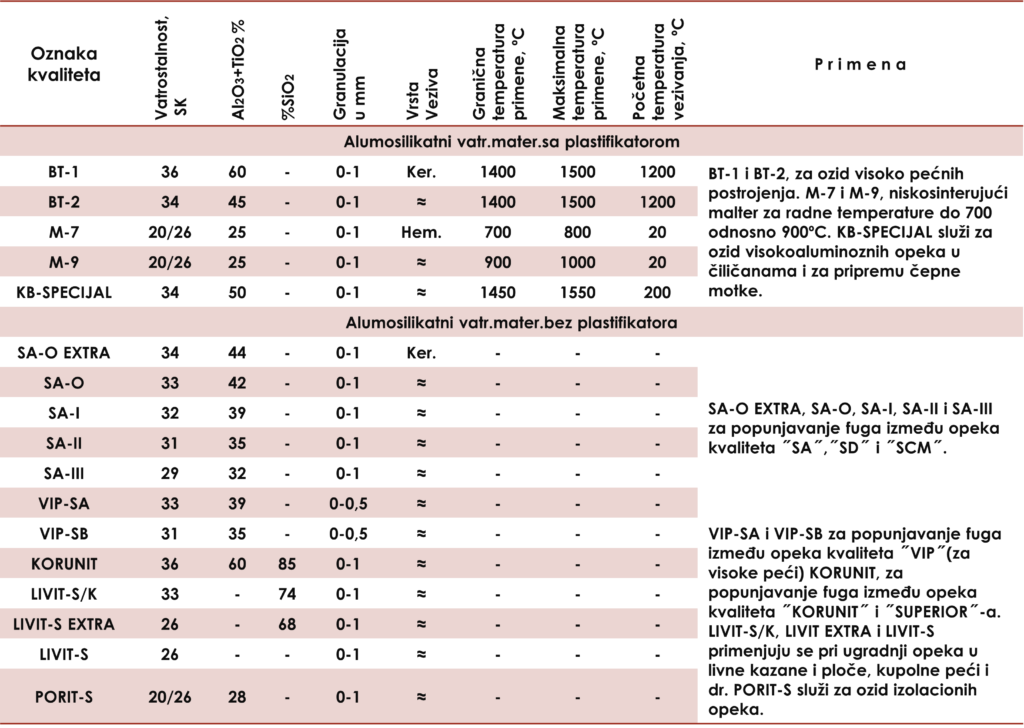

ALUMOSILICATE REFRACTORY MASSES AND CONCRETES

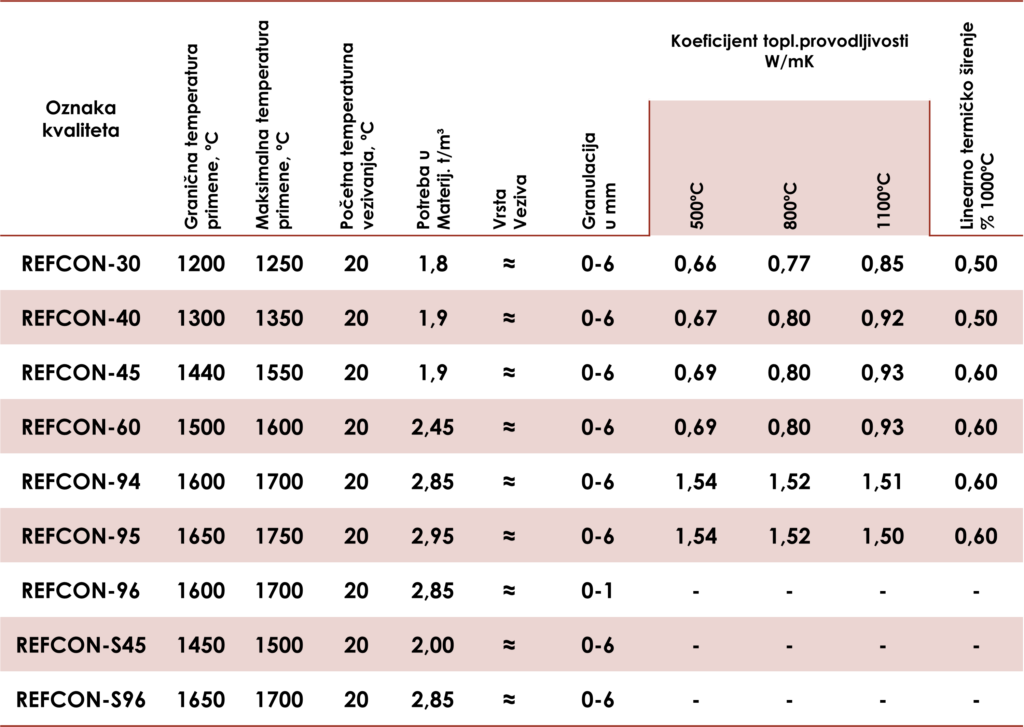

Refractory concretes harden even at ordinary temperatures, so they are suitable for quick repairs of masonry. They are used for the production of linings for tunnel wagons, for the thermal insulation of furnaces, for the production of flues, for linings that are exposed to strong earthquakes and shocks, etc.

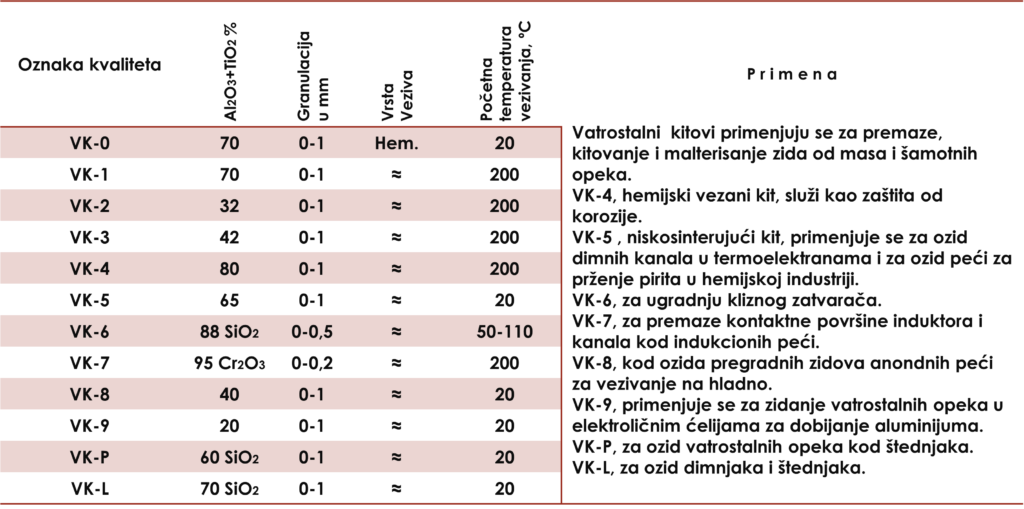

USE:

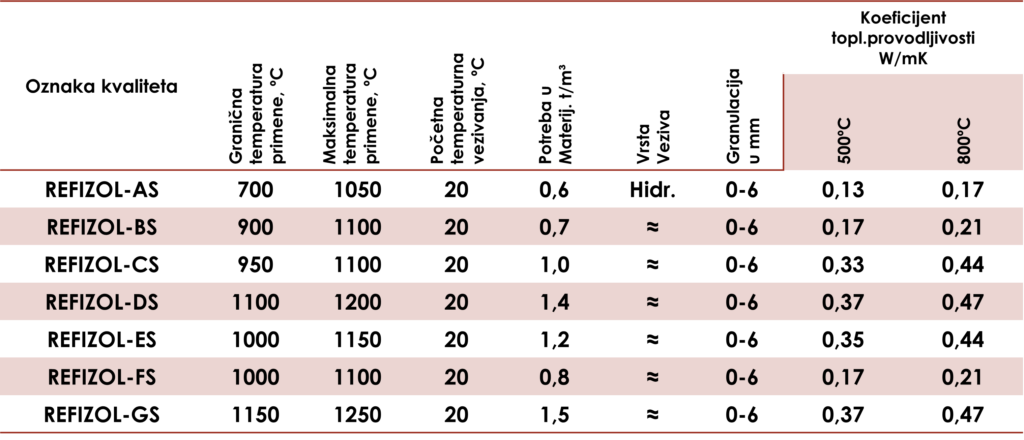

These concretes can successfully replace thermal insulation bricks, and are used for thermal insulation of thermal plants. The hydraulic connection provides a permanent lining.

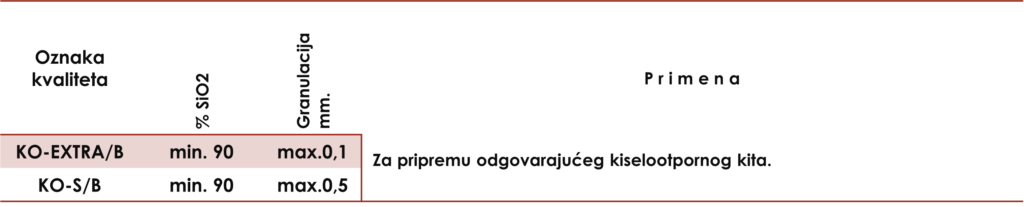

USE:

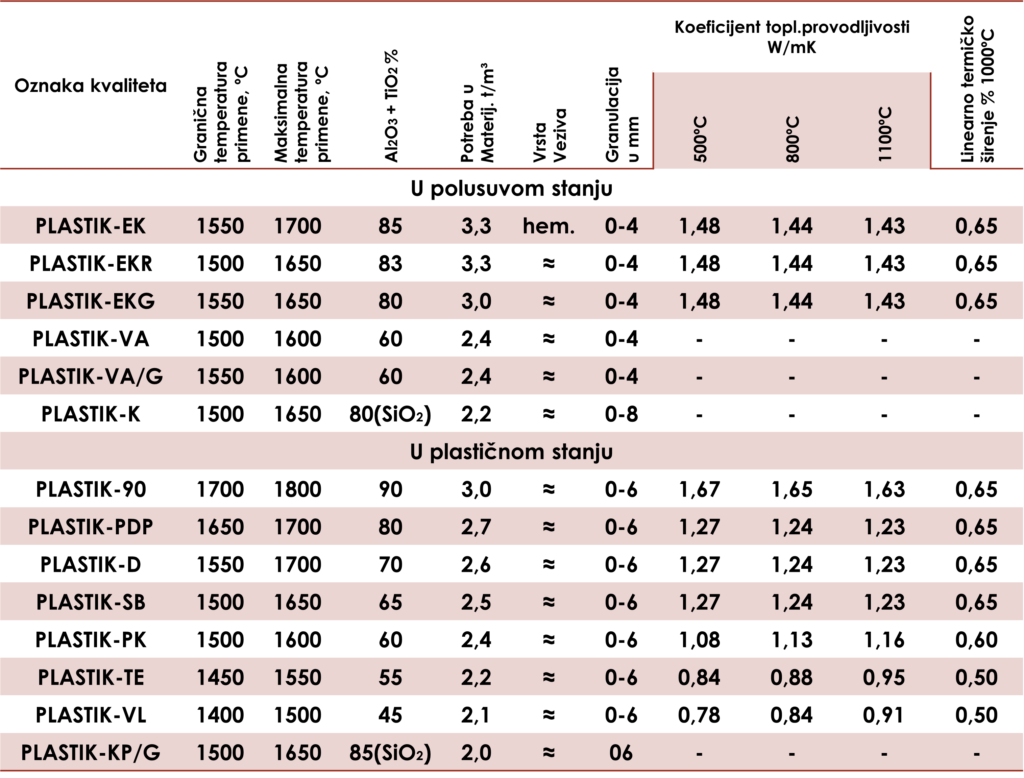

Note: The storage time of PLASTIK mass is 3 months

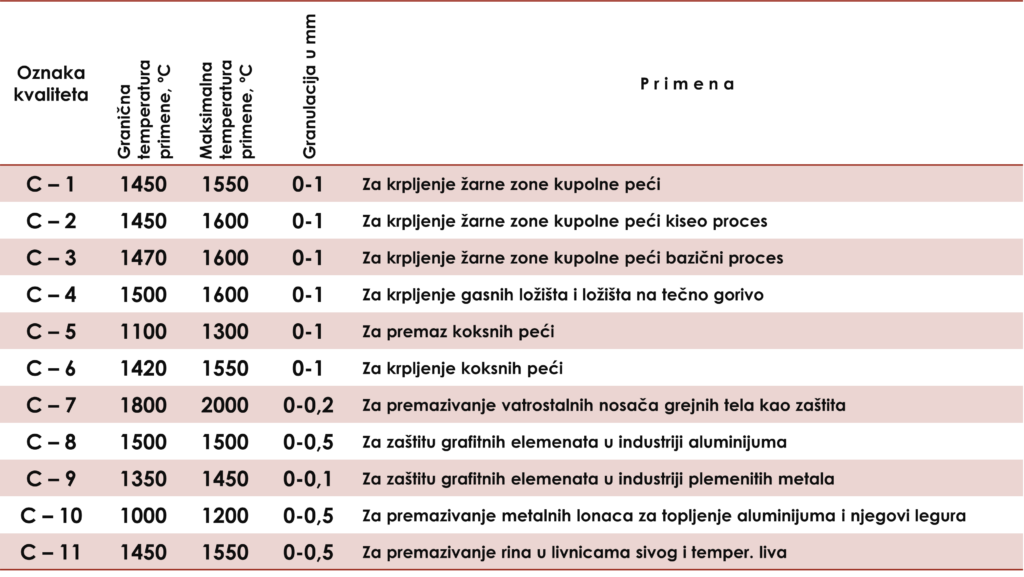

USE:

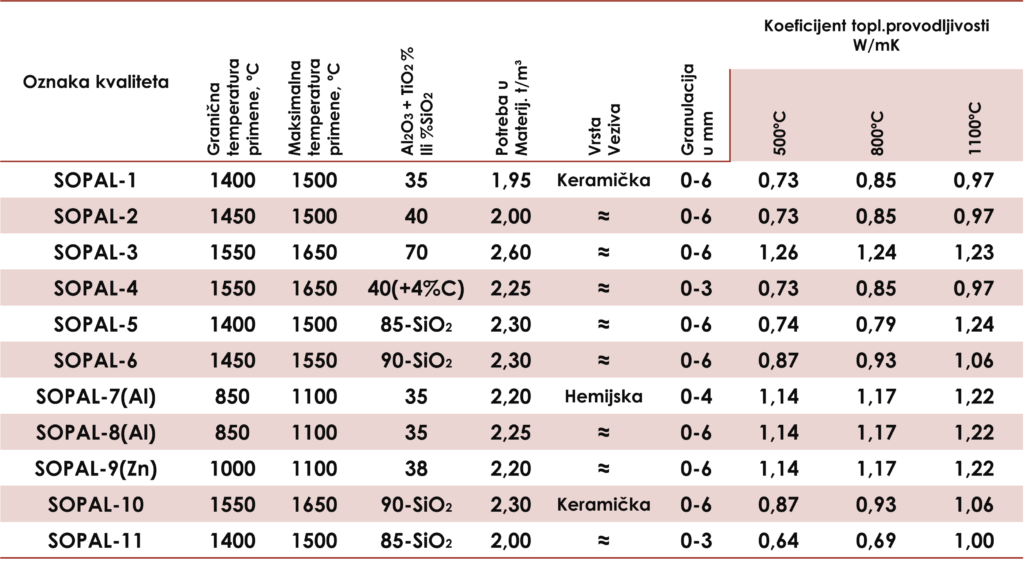

NOTE:

BDV REFRACTORY is the successor of "Keramika-Gavrilović" , which has been present on the market since 1993 as a producer of technical ceramics. In an area rich in deposits of refractory clays, where the industry of refractory materials has developed, by expanding capacity we have completed the production program with fireclay bricks of standard and special formats, as well as refractory concrete and masses for the needs of non-ferrous and ferrous metallurgy, foundries, brickworks, sugar factories, oil factories, thermal power plant…

Developed by 2A Design