Chamotte bricks have wide application in the most different branches of the industry.

They have the fire proofness and resistance to higher temperature exposure,

required chemical structure, little porousness and excellent durability when exposed to sudden thermal shocks.

They are being produced by plastic and half dry method in all forms

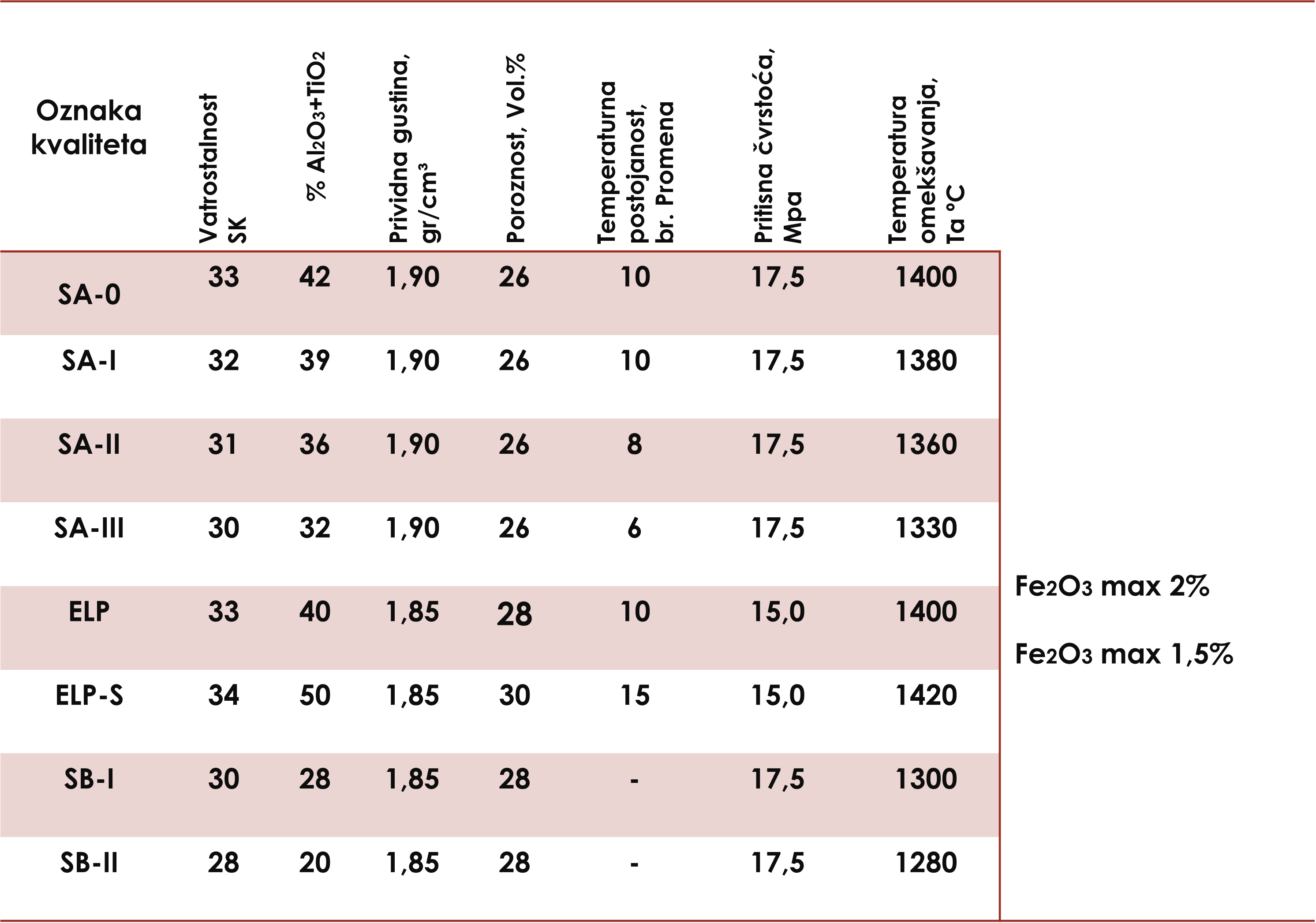

Chamotte bricks of SA-O, SA-I, SA-II and SA-II quality groups are highly used during the building of different thermal aggregates for which there are no special requests related to mechanical resistance, such as resistance to abrasive materials (cinder, melted metal and glass effect…); for example, heating and induration furnaces Steam boiler, ceramic and brick furnaces, smoke channels…

ELP quality bricks are specially designed for the application in electro furnaces and they have low ratio of Fe2O3.

SB quality is being applied in chemical industry for coke batteries walling, smoke channels, Steam boilers’ beds etc..

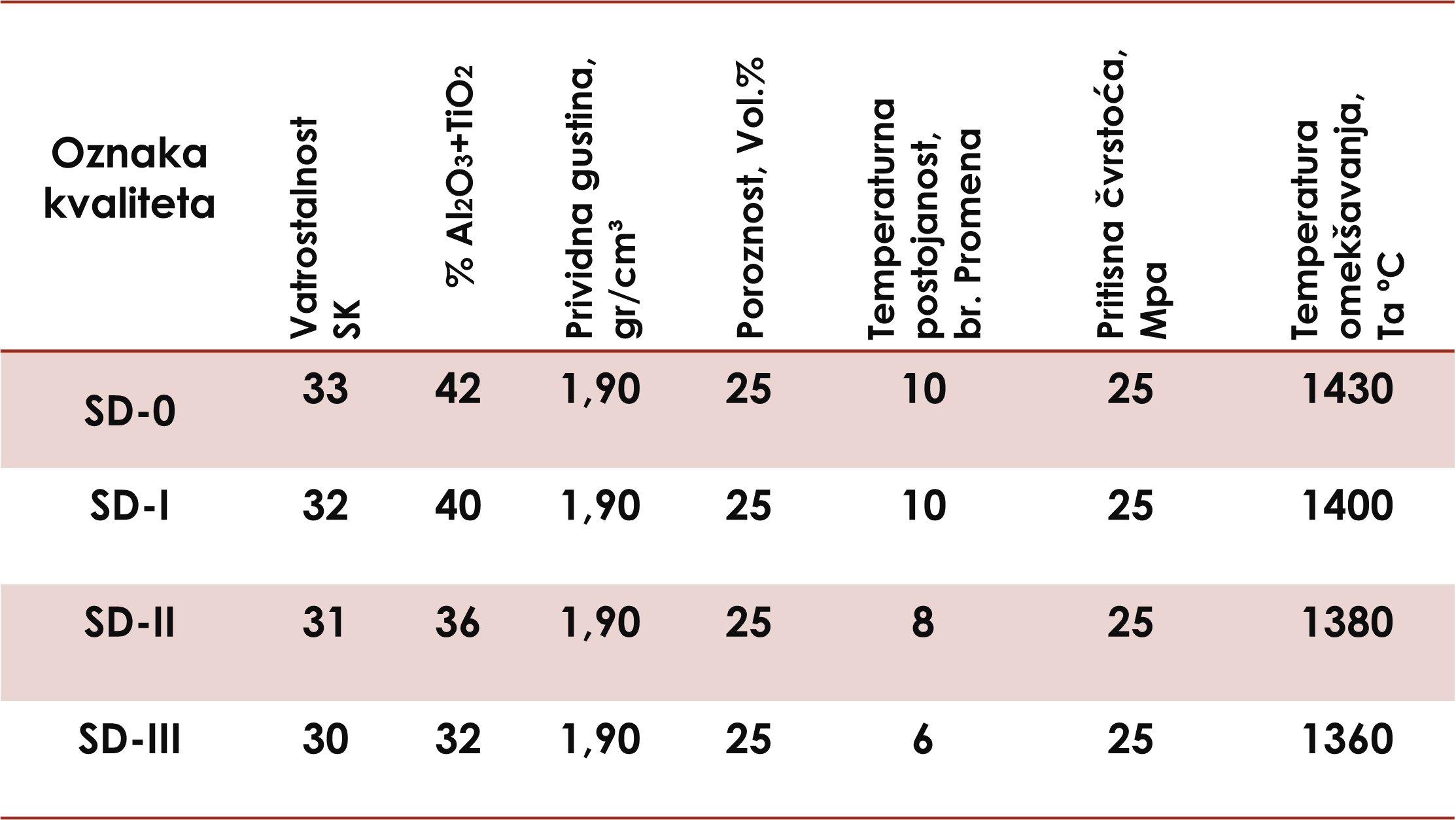

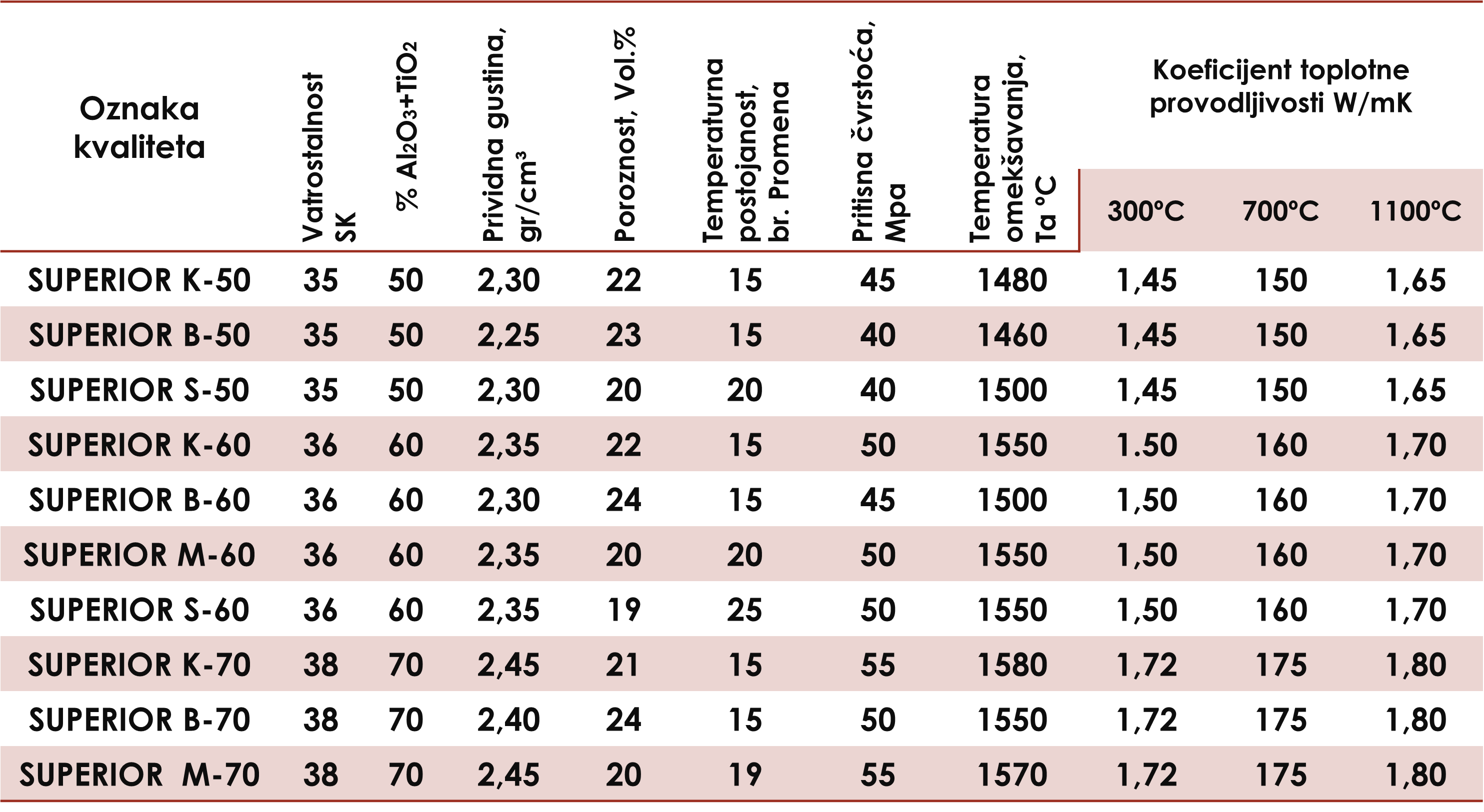

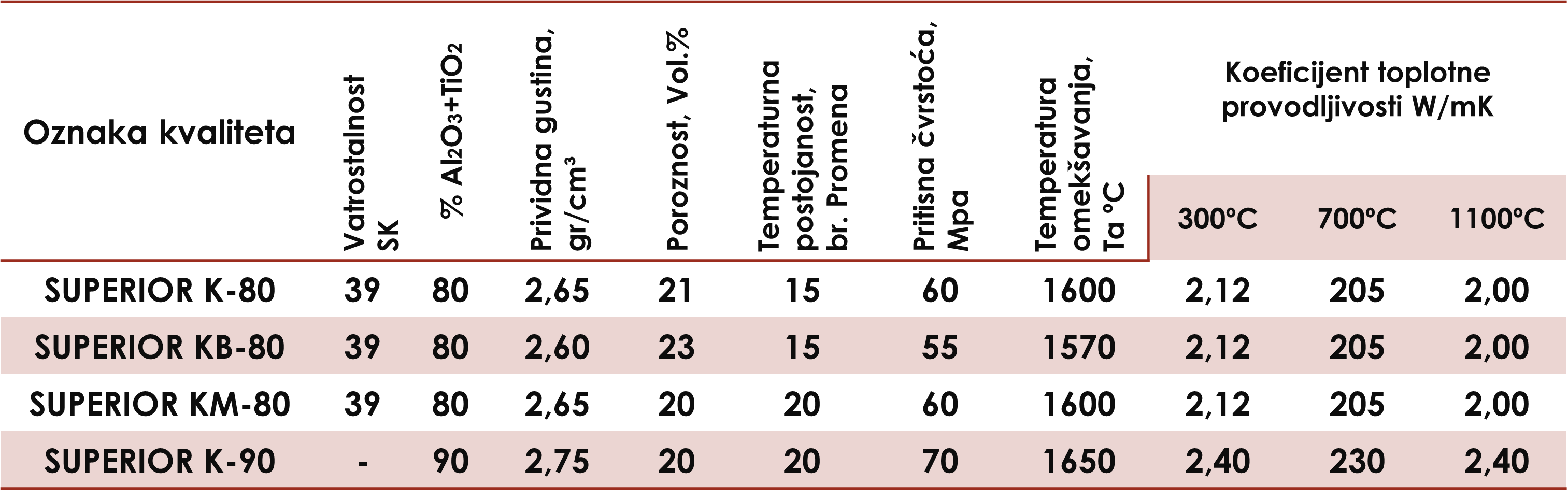

Bricks of this type have the necessary fire resistance and stability under load at high temperatures, the required chemical composition, relatively low porosity, good compressive strength and high resistance to temperature changes.

They are widely used in all industrial furnaces, especially for the walls of tunnel and chamber furnaces for the ceramic industry, deep, annealing and quenching furnaces in ferrous and non-ferrous metallurgy.

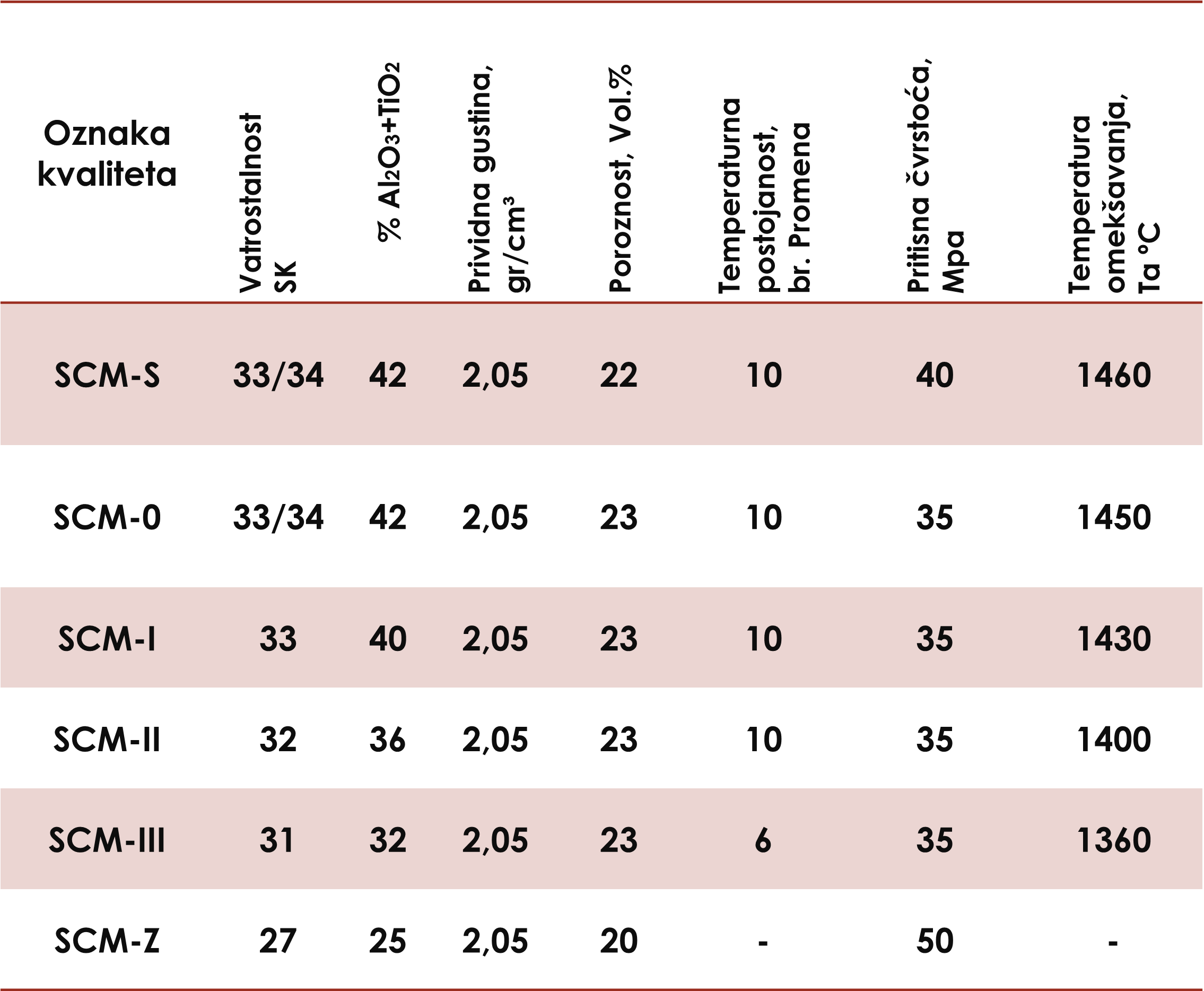

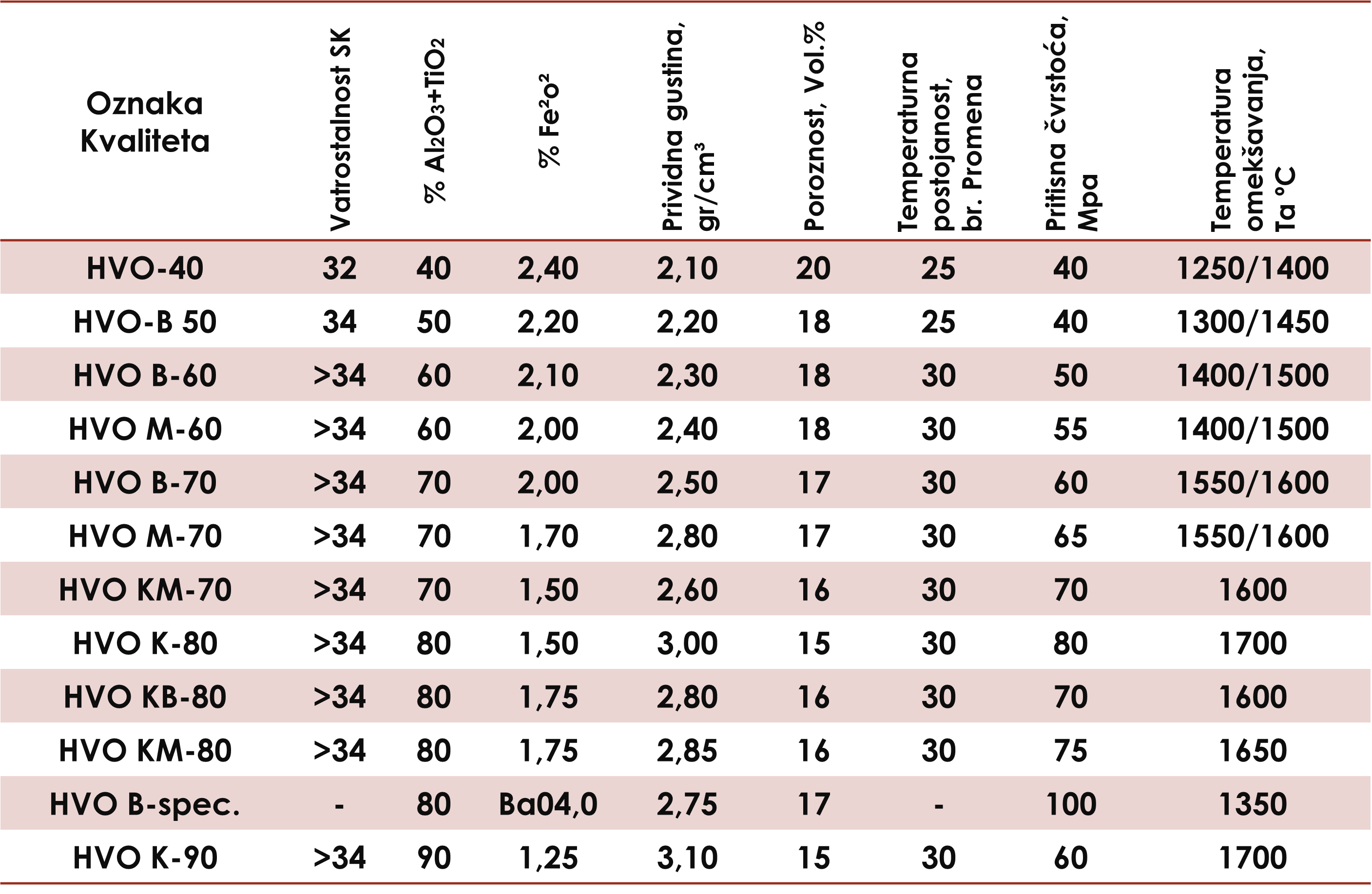

As the name suggests, these are bricks made by a special technological procedure, from highly suspended refractory masses, on high-pressure presses or pneumatic compaction, which provides them with a homogeneous structure, high density and high compressive strength. In these bricks, wear resistance is particularly pronounced.

Bricks „SCM“ are used in rotary liln and shaft-furnace in the industry of cement, lime, caustic and sitered magnesite, in the hearth of boilers whose fuel is coal dust, as well as for parts exposed at high temperature. They are recomended for all thermal aggregates, where refractory brickwork is submitted to thermal, chemical and mechanical wear.

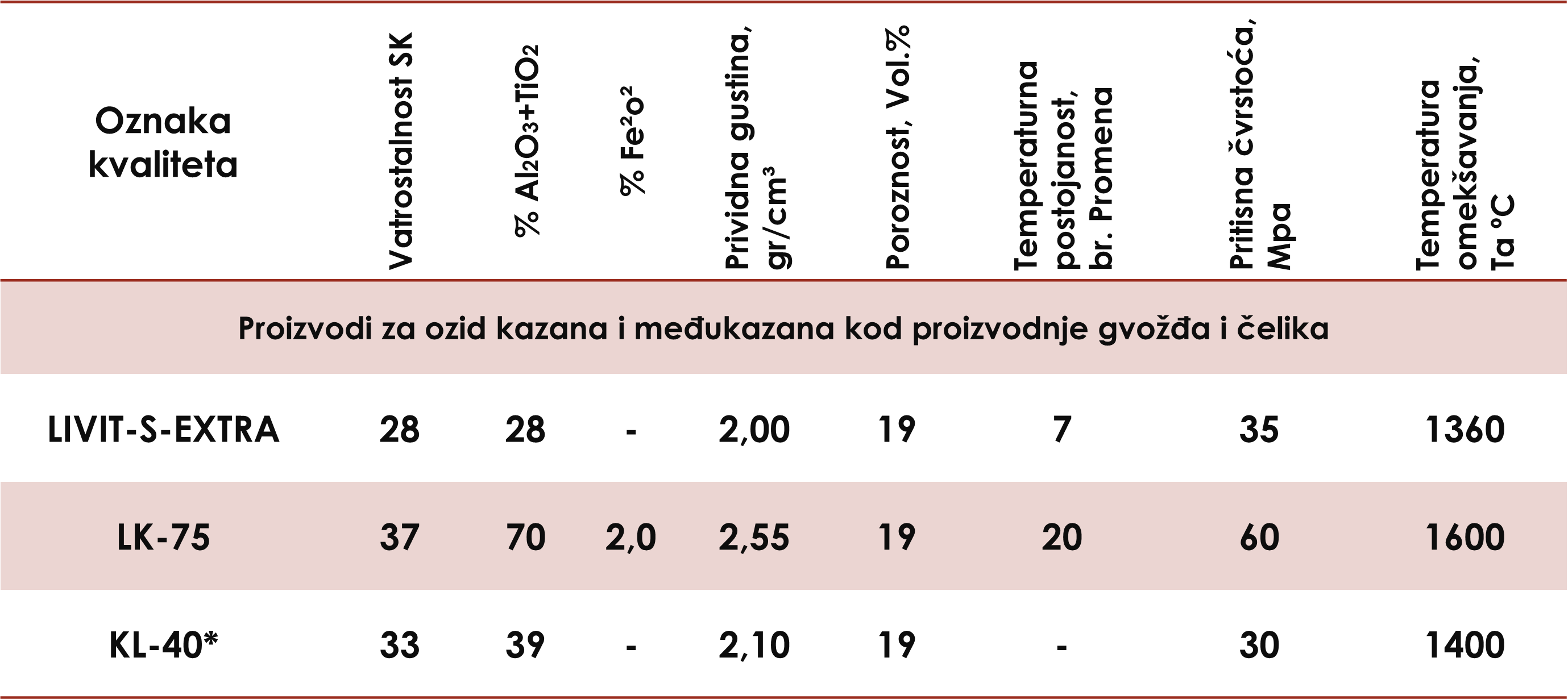

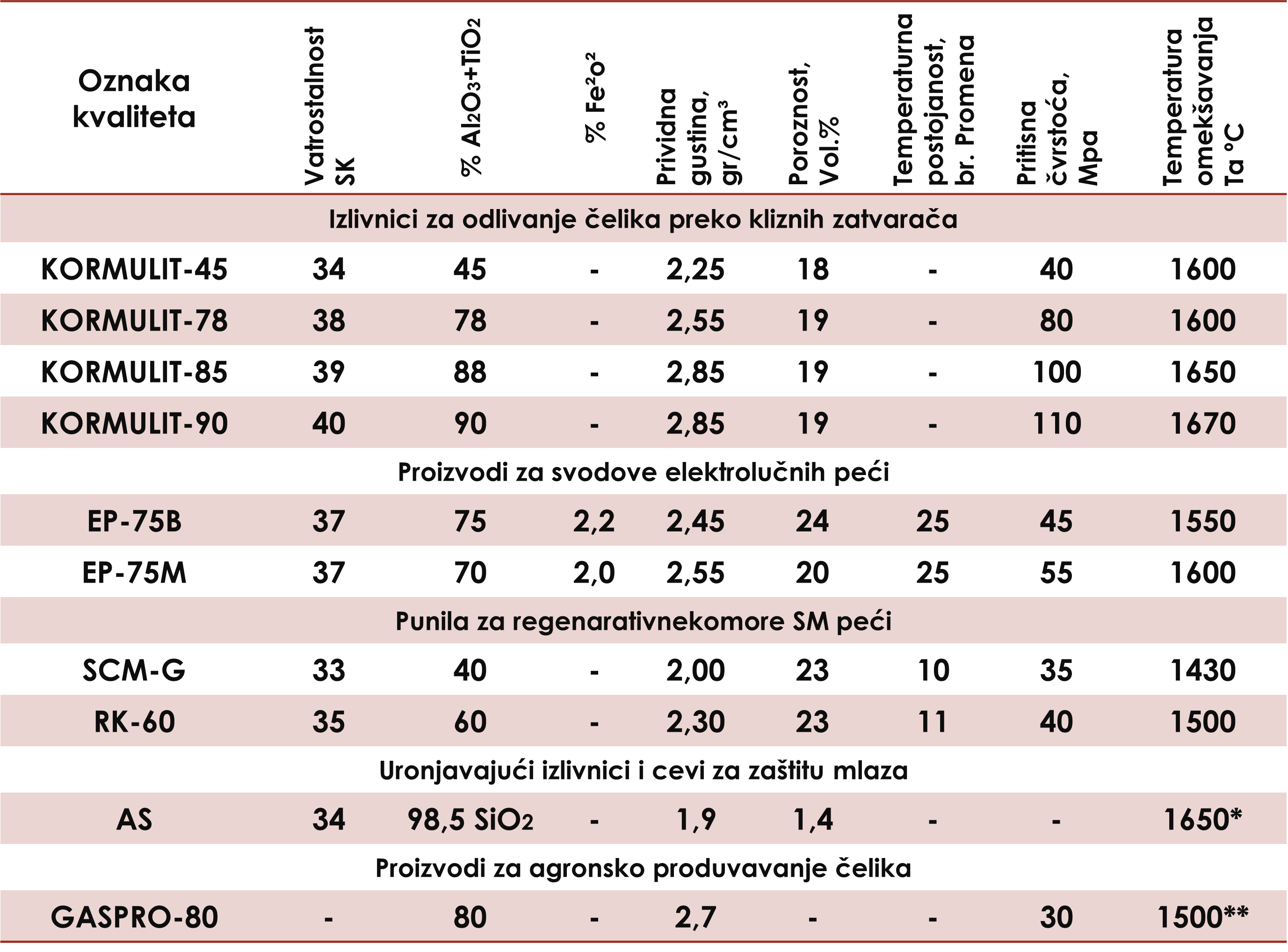

They are produced in standard formats as well as based on the project or customer needs, semi-dry and plastic process. A special feature of these qualities lies in the high resistance to the action of molten metals, with satisfactory resistance to temperature changes.

For products of these qualities, high-value raw materials are used, such as: sinter bauxite, electroheated corundum, etc.

Linearno termičko širenje, na 1400ºC : 0,8-1,1%

Srednja specifična toplota, kJ/kg ºK

20 – 300ºC 1,00

20 – 700ºC 1,05

20 – 1100ºC 1,10

chemical industry

paper and coke batery industry

industry of oil, grease and soap

Light insulating bricks, in addition to being used as a thermal insulation material, are also successfully used for refractory walls in those thermal aggregates where there are no chemical reactions and mechanical stresses, where the criterion for selecting bricks is the height of the operating temperature.

NOTE: Podaci za fizičko-termičke osobine dati napred u tabelama za sve kvalitete dobijeni su kao prosečne vrednosti na probnim telima izvađenih iz normalnih opeka ili njima sličnim formatima.

Ove vrednosti ne mogu se primeniti i na druge komplikovanije formate opeka.

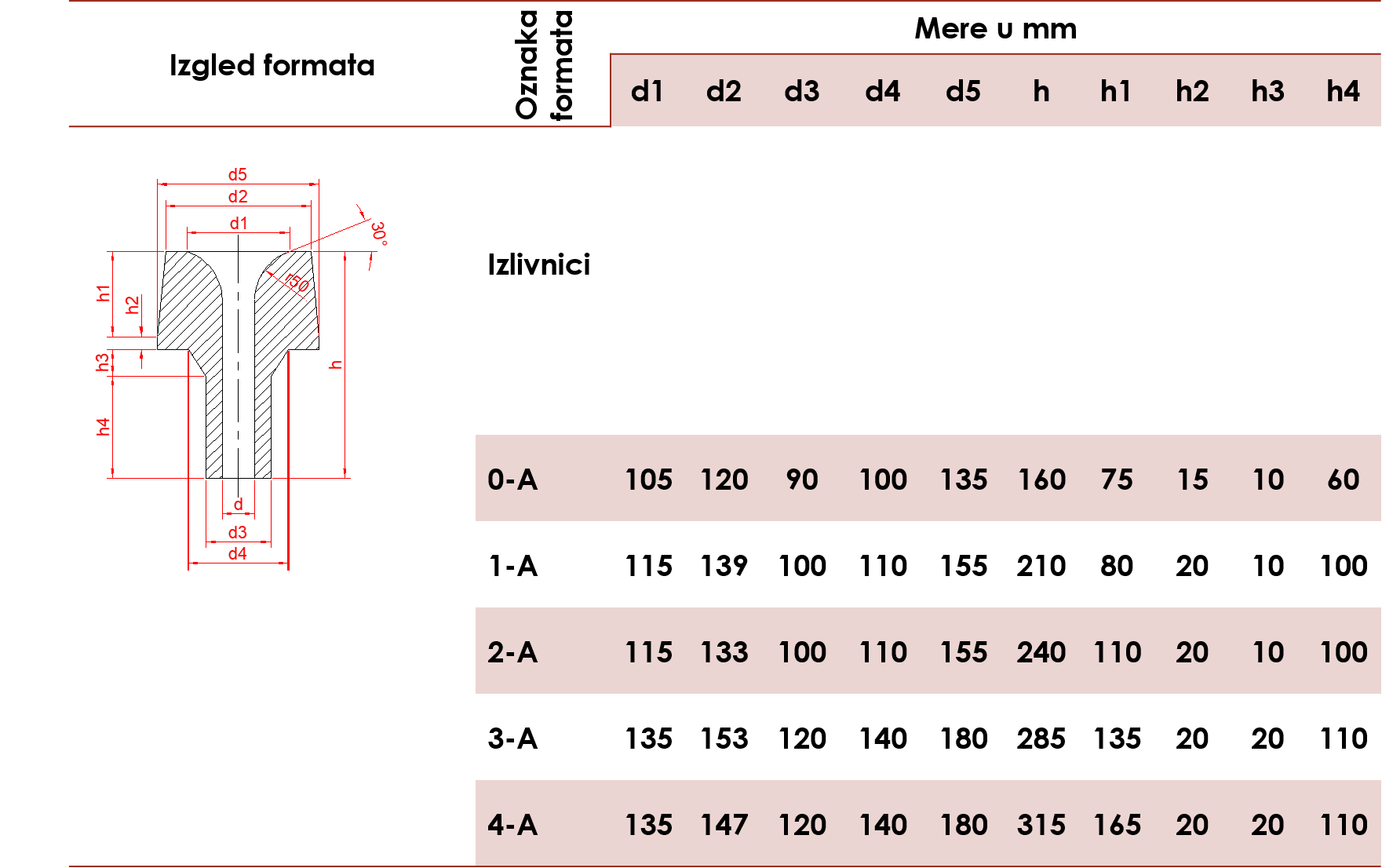

They are used in the production of steel castings in casting molds.

The application of the inflow system guarantees:

-high quality products

-cleanness of castings

-increase performance

-reduces scrap

-reduces production costs

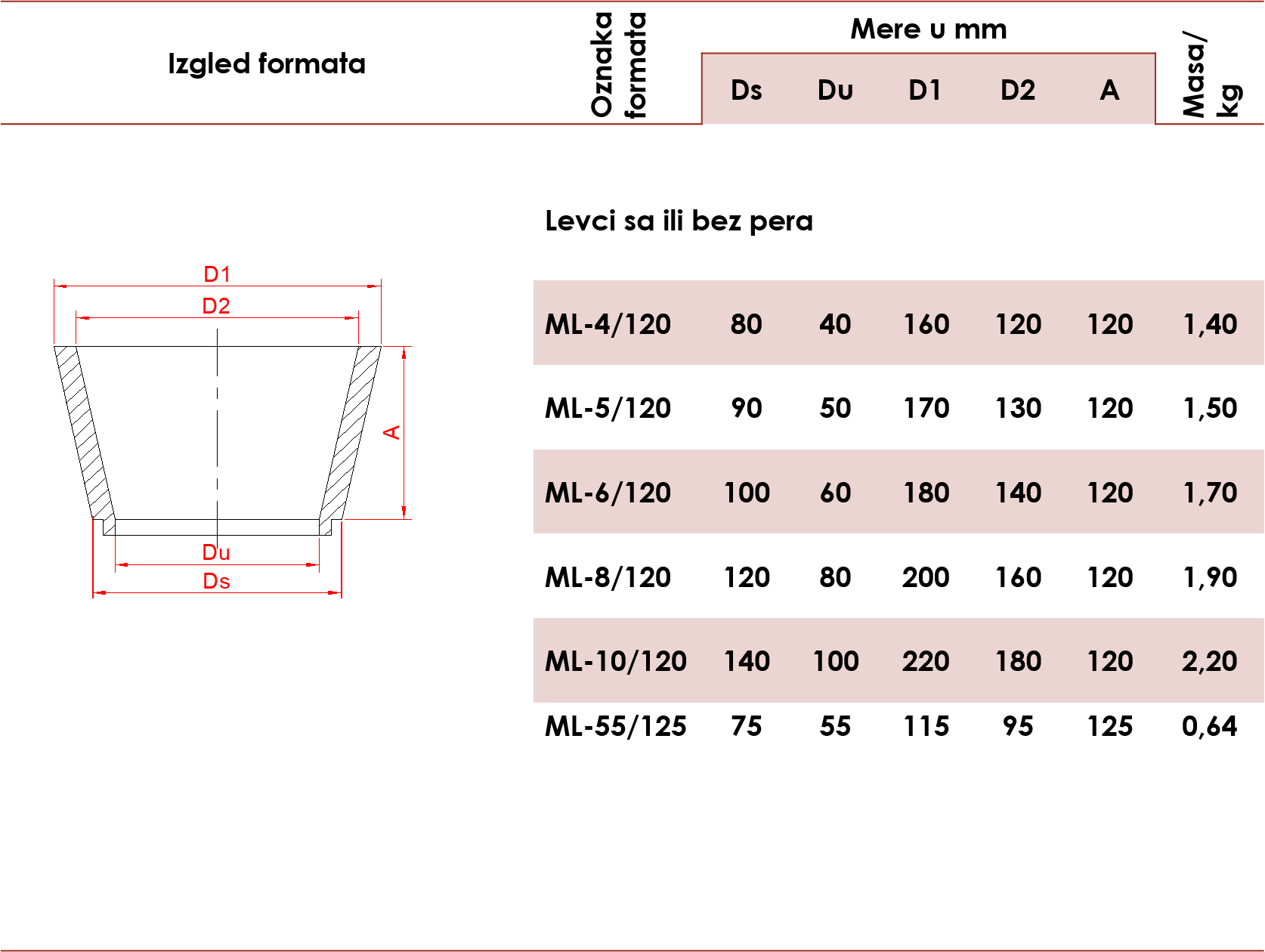

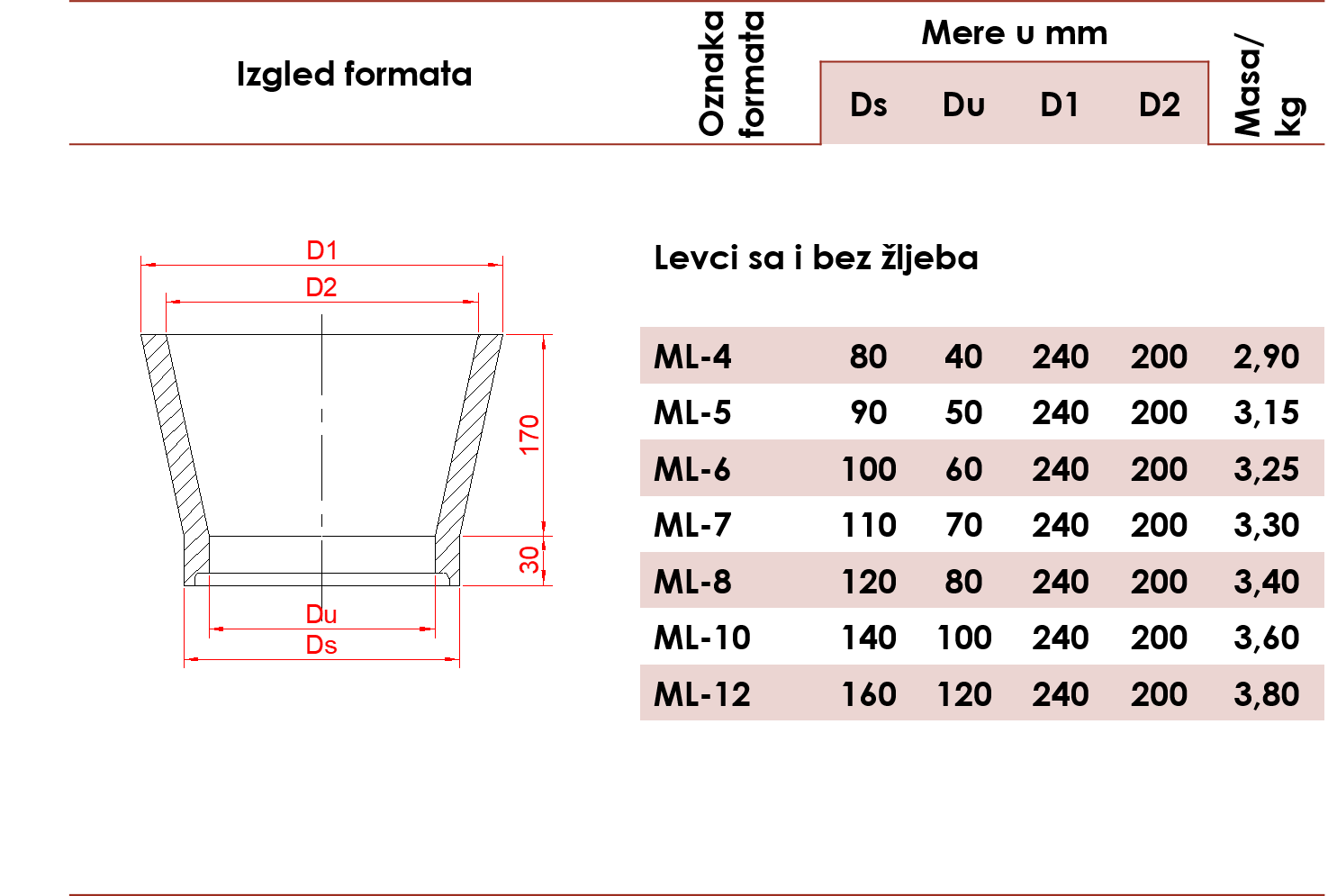

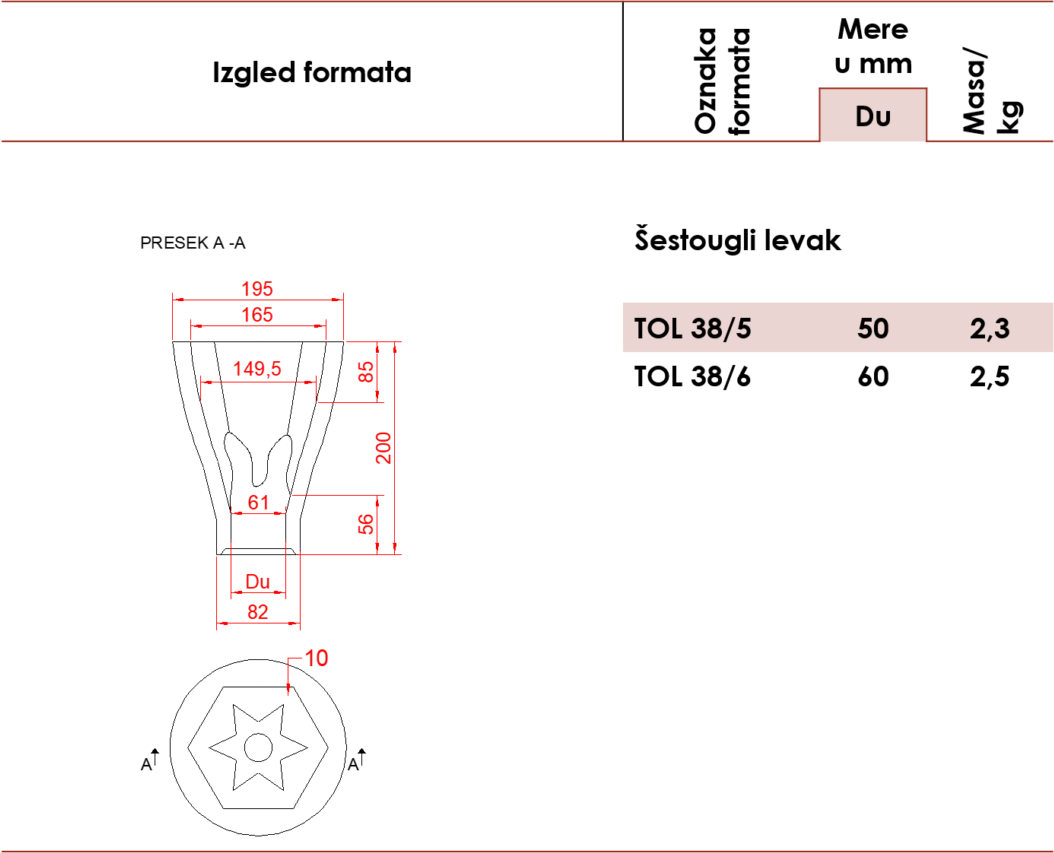

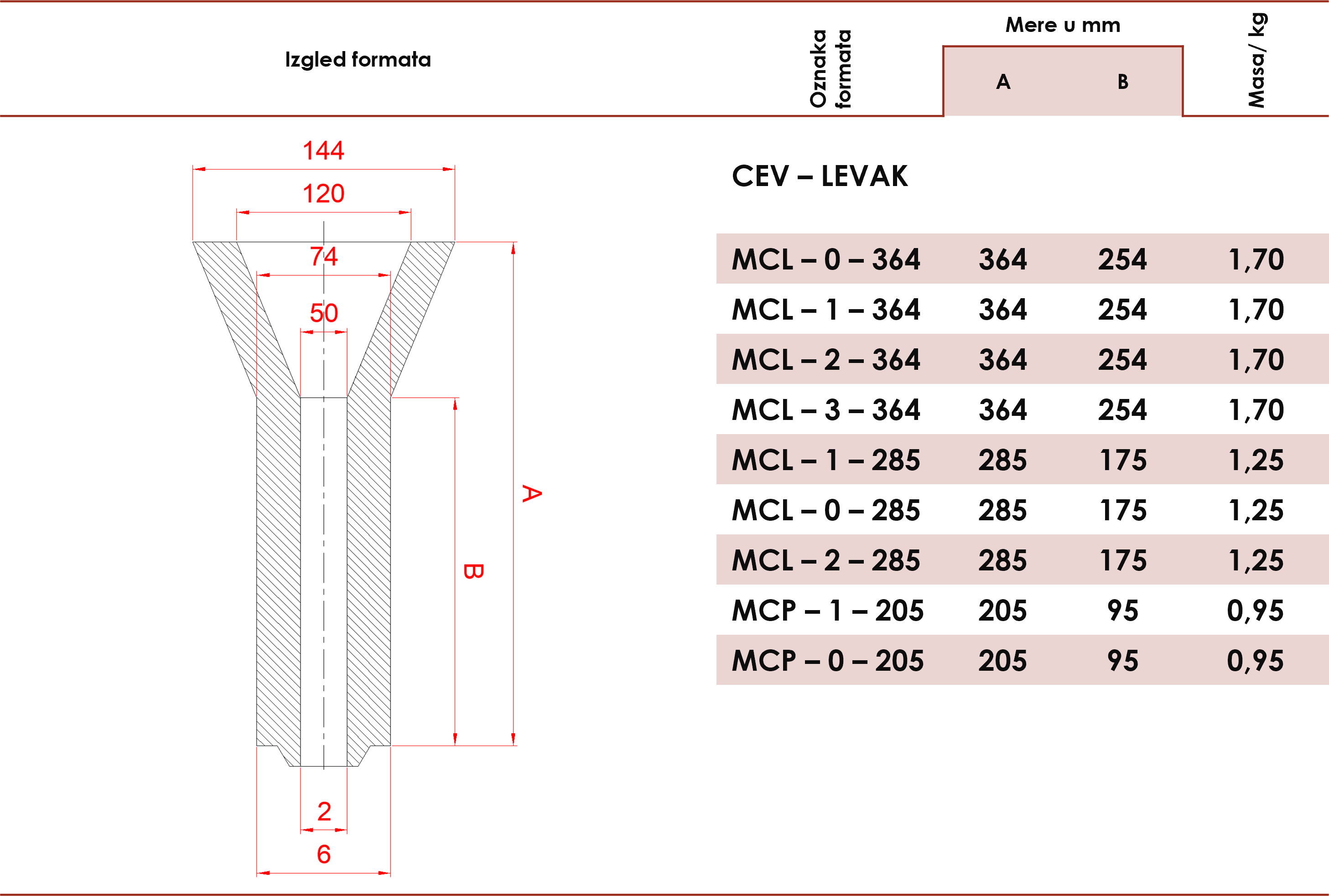

NOTE: Oznaka odgovara levku sa perom, a na zahtev potrošača isporučujemo i levke bez pera.

ML-55/125 radi se bez pera.

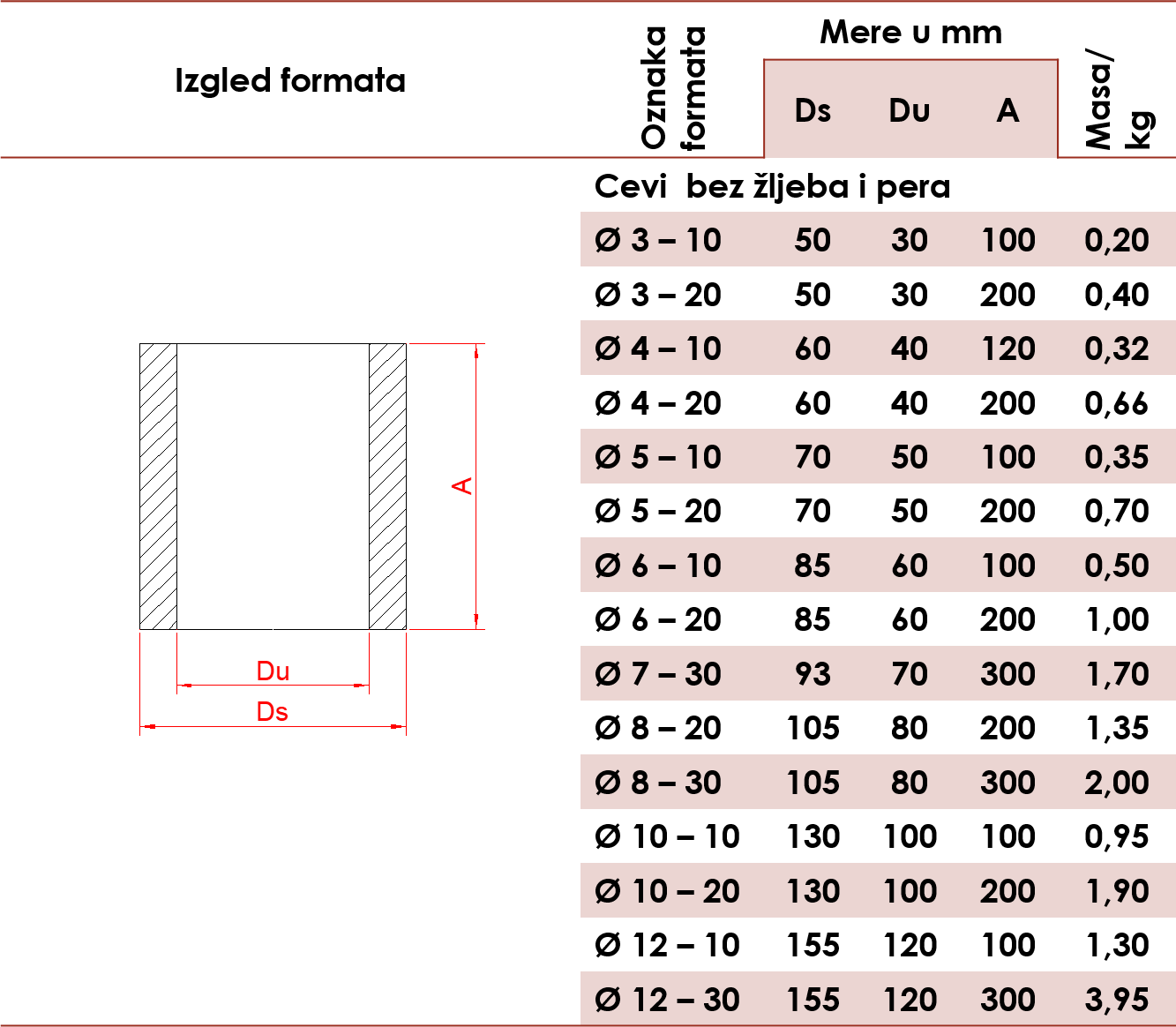

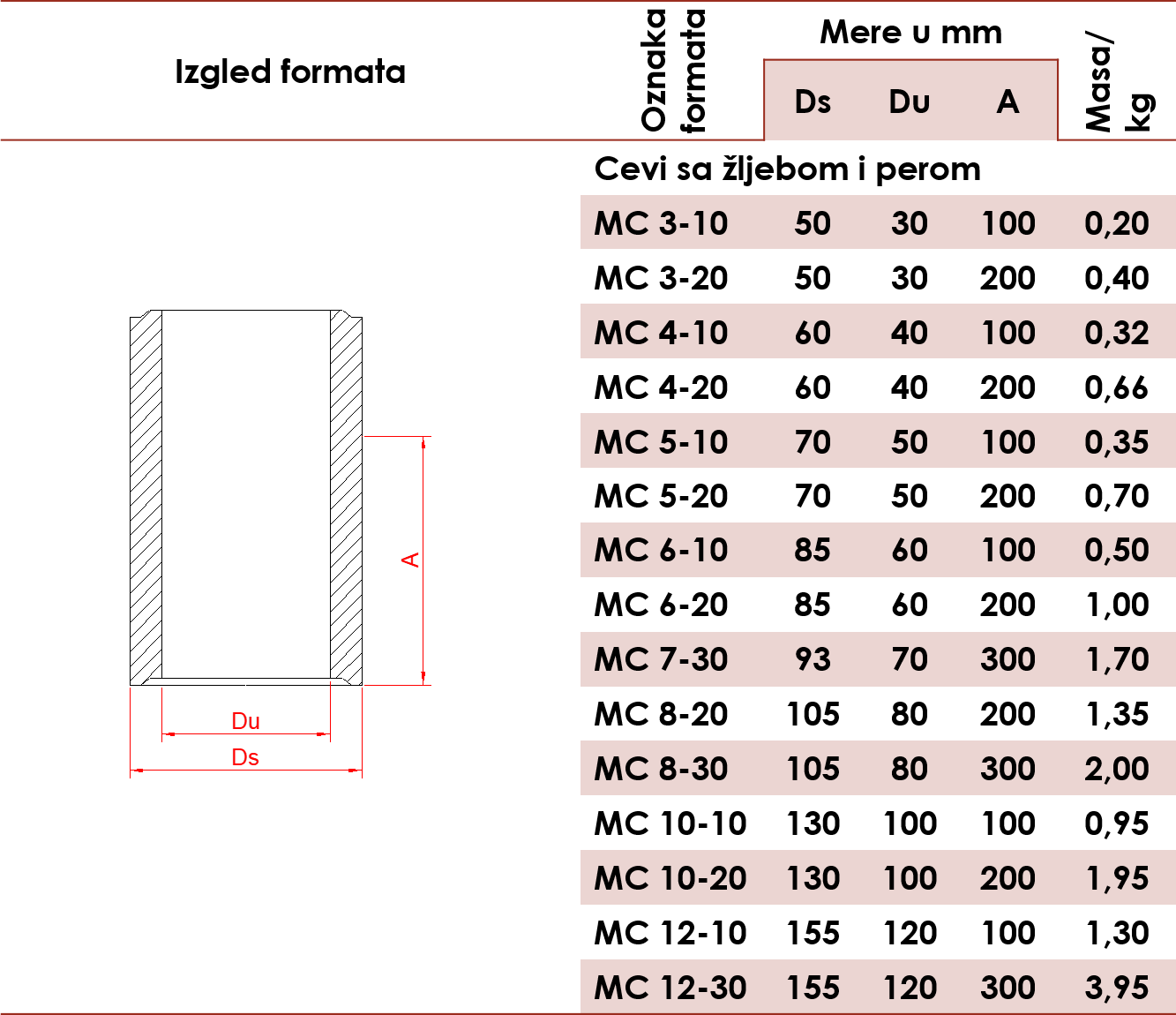

NOTE: Proizvodimo cevi svih dužina /A/ od:

50 – 200mm za Du = 30mm

50 – 300mm za Du preko 30mm

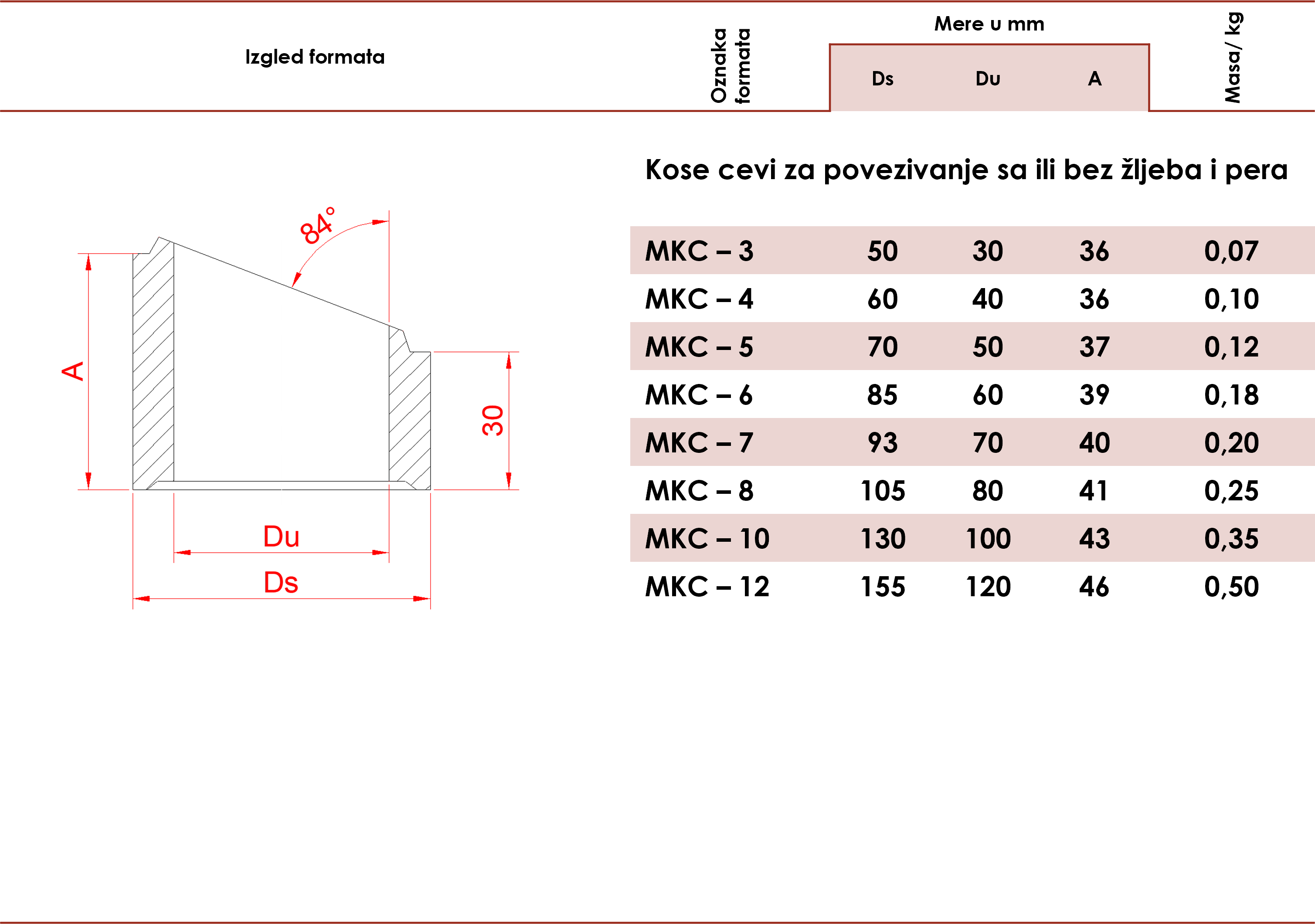

NOTE: Oznaka odgovara cevima sa žljebom i perom, a na zahtev potrošača isporučujemo i cevi bez pera i žljeba.

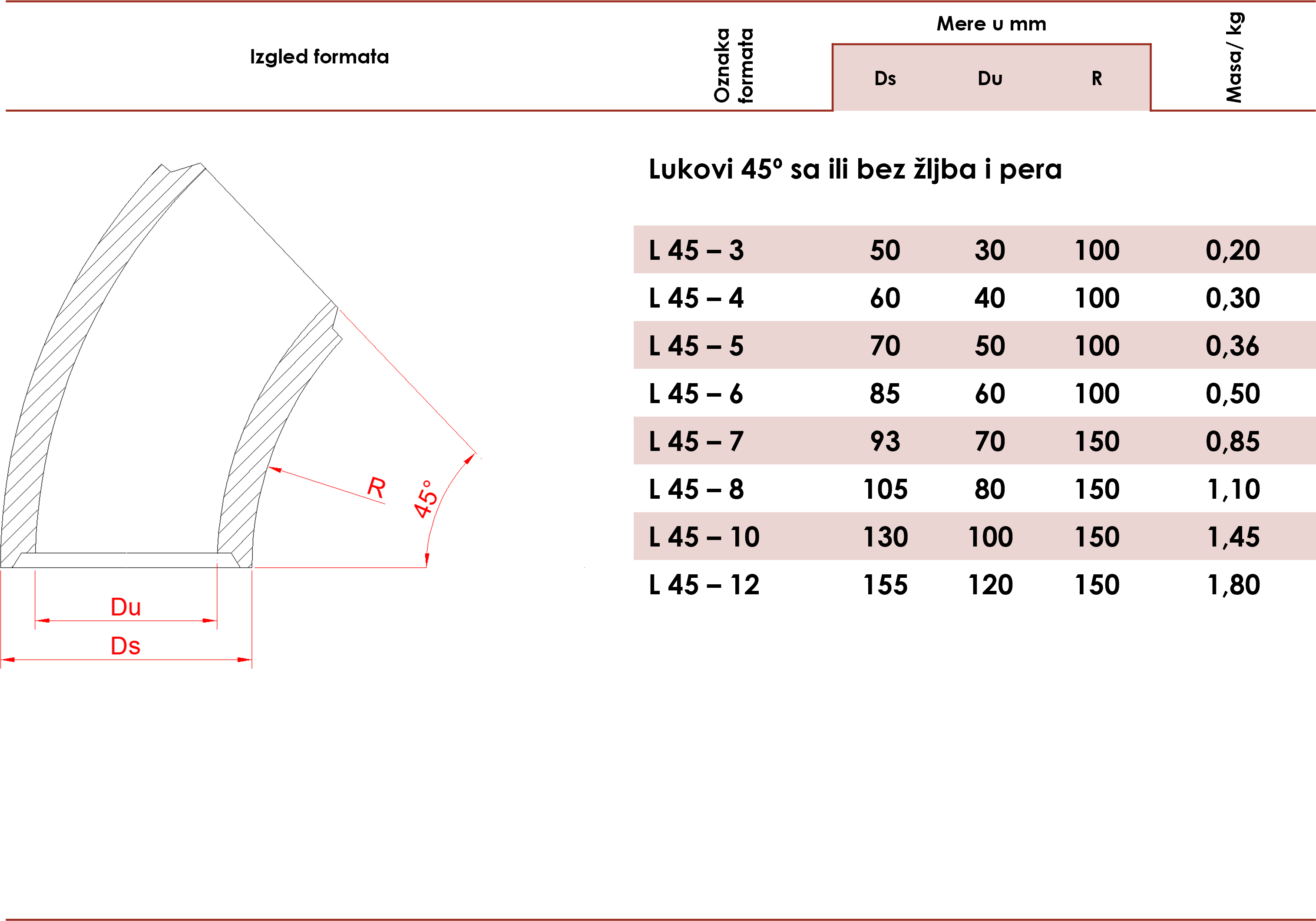

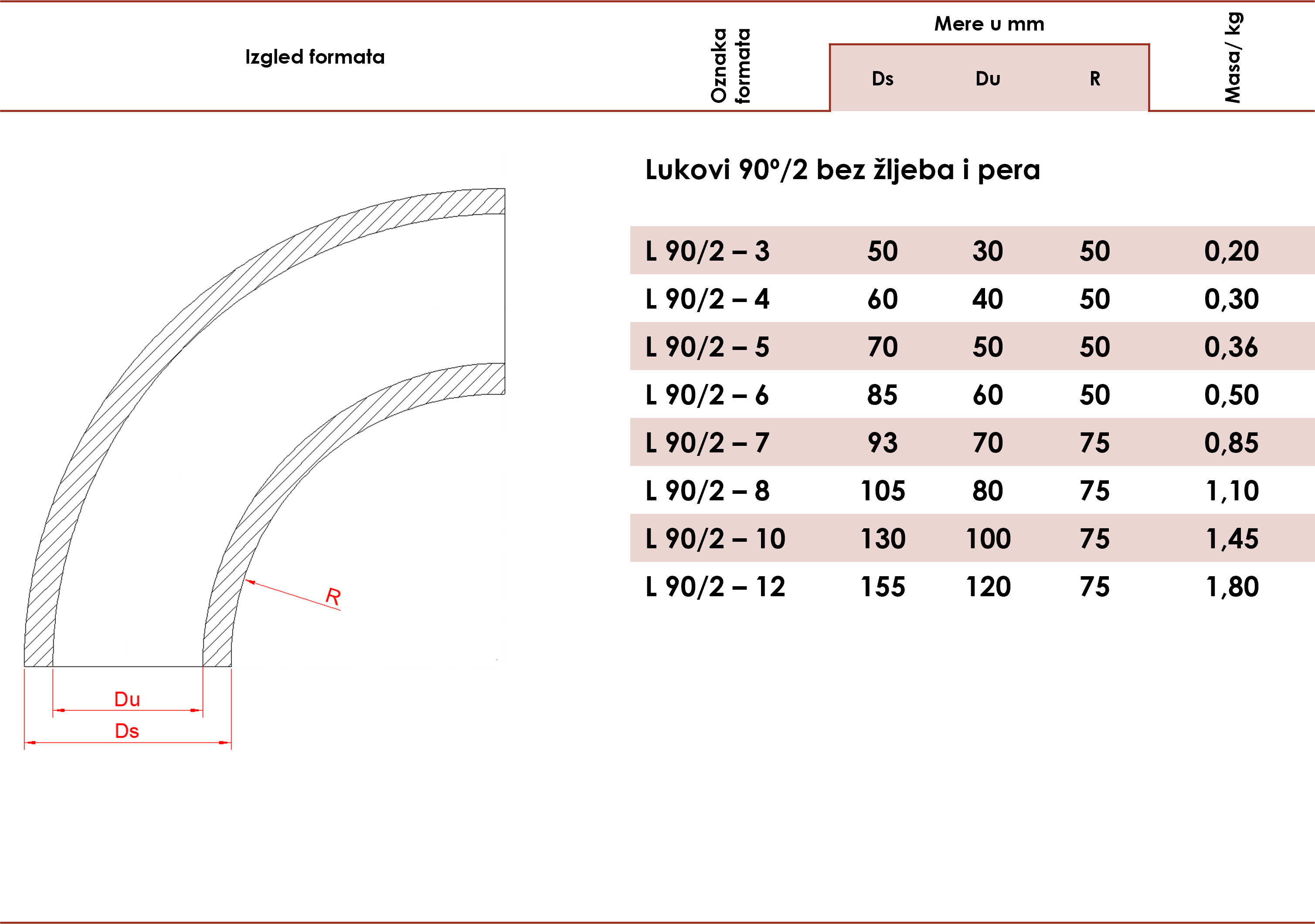

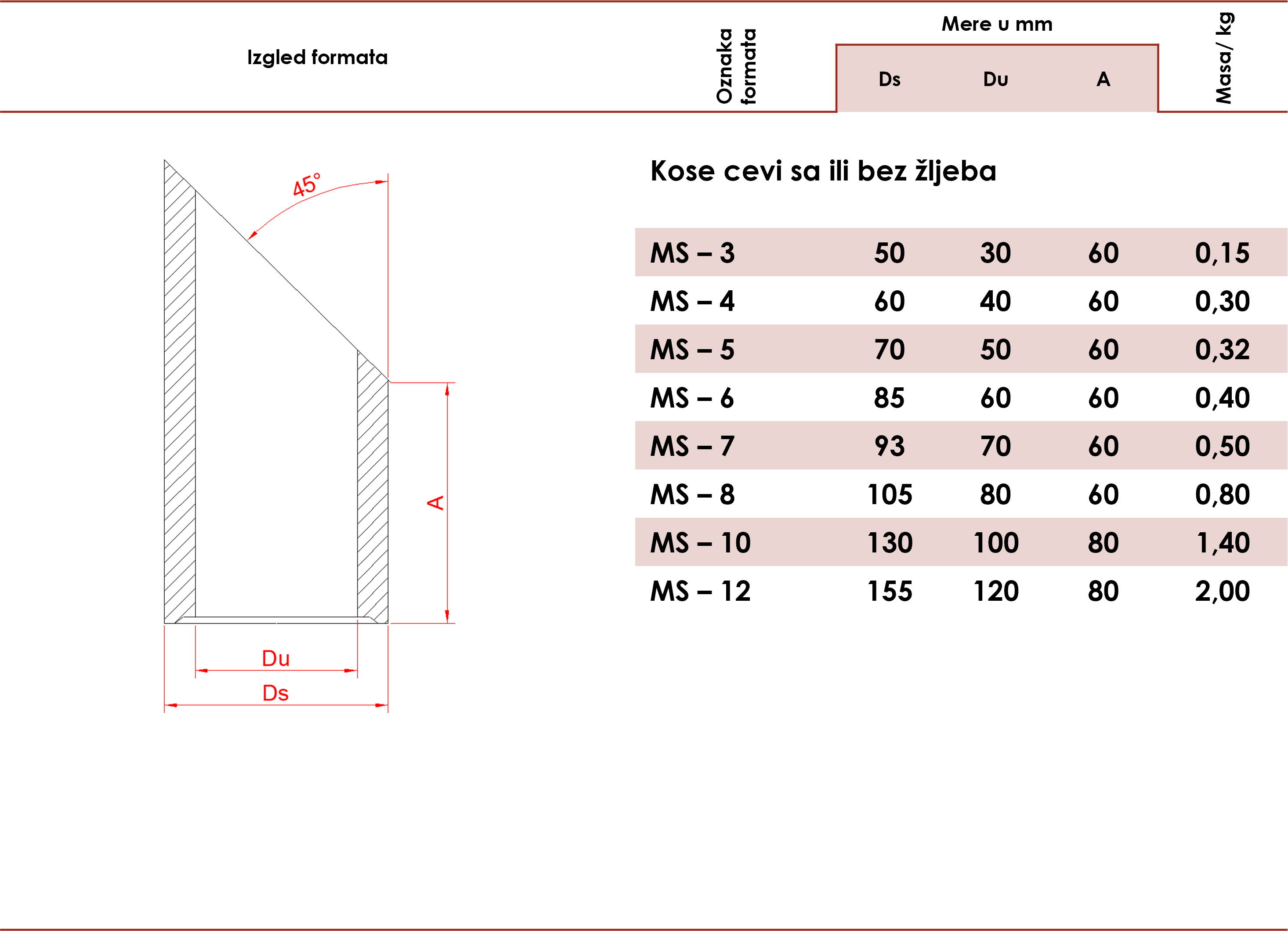

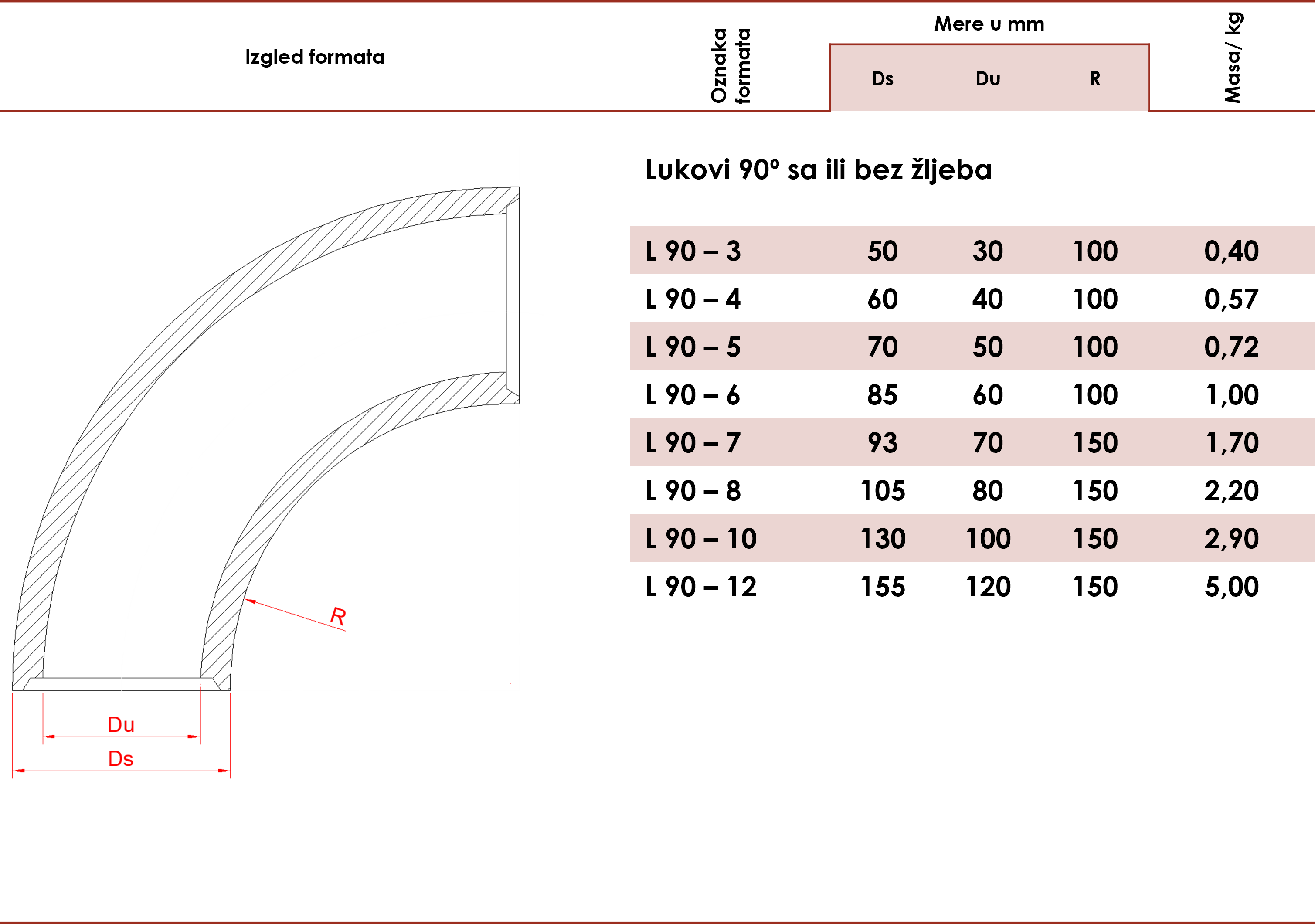

NOTE: Oznaka odgovara luku sa žljebom i perom, a na zahtev potrošača proizvodimo i luk bez pera i žljeba.

NOTE: Oznaka odgovara levku sa žljebom , a na zahtev potrošača isporučujemo i levke bez žljeba.

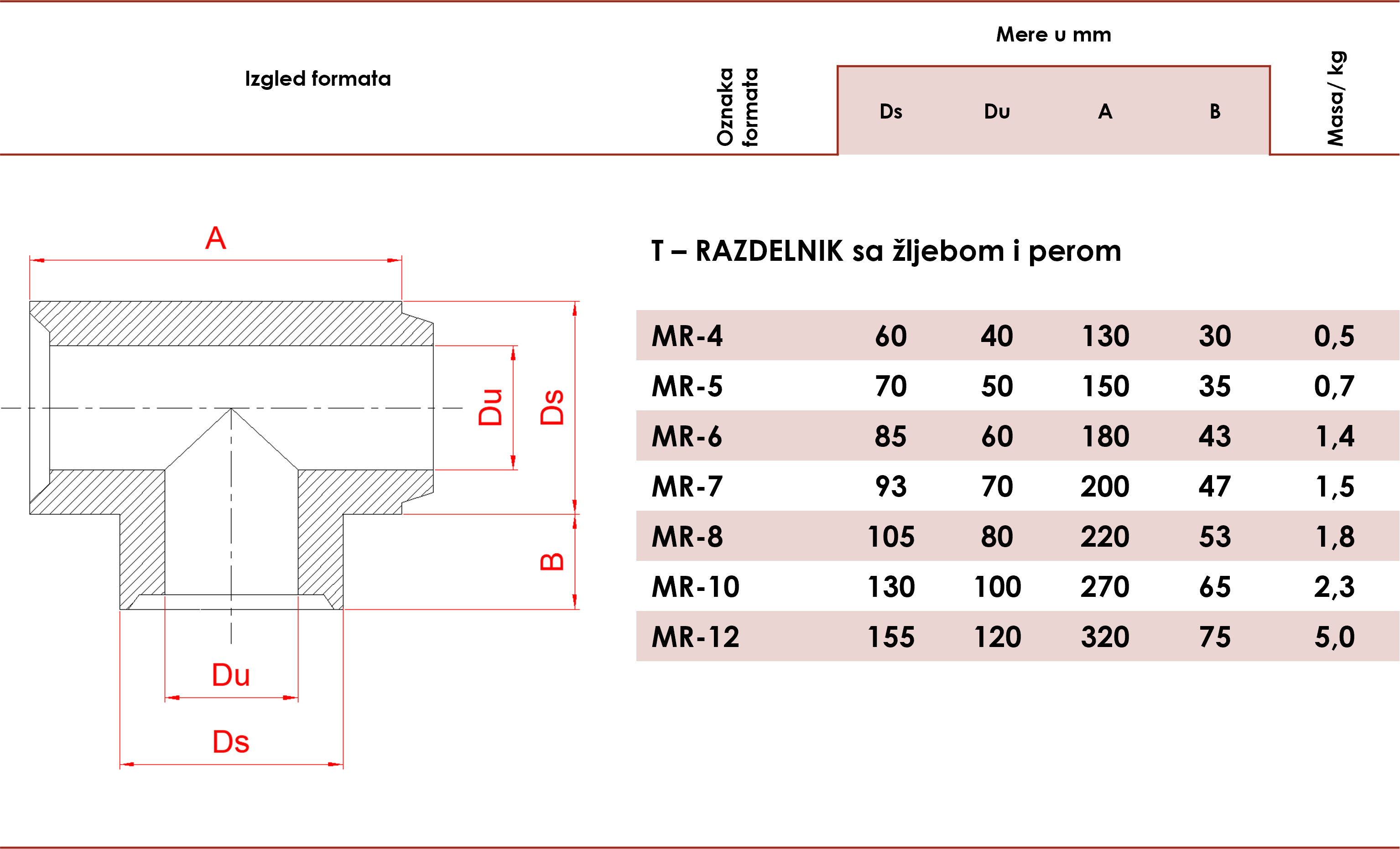

NOTE: Žljeb se uklapa sa perom svih formata un pprečnika 60mm kao i TOL 38/6.

NOTE: Proizvodimo cevi svih dužina /A/ od:

50 – 200mm za Du = 30mm

50 – 300mm za Du preko 30mm

NOTE: Oznaka odgovara luku sa žljebom , a na zahtev potrošača proizvodimo i luk bez žljeba.

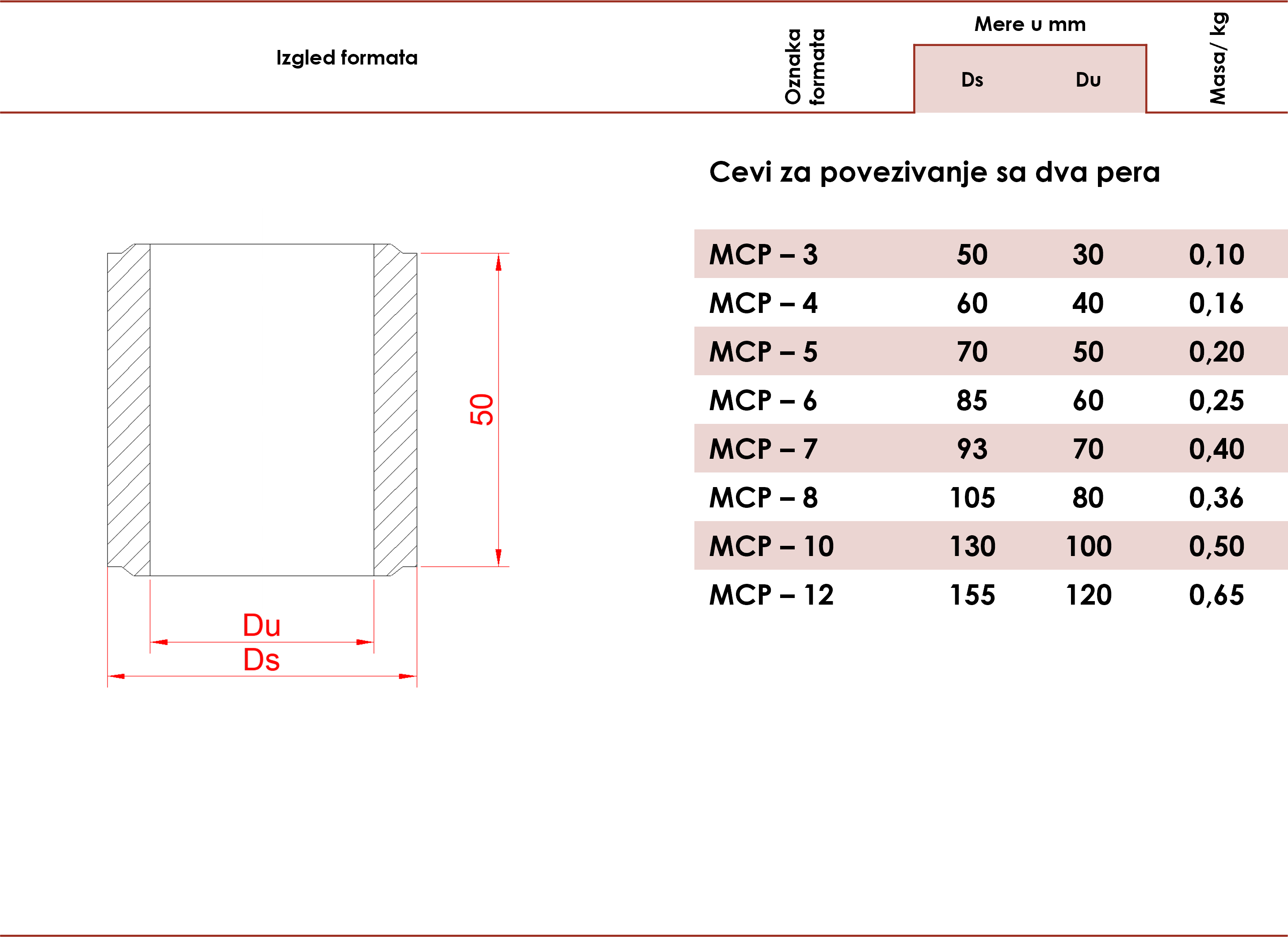

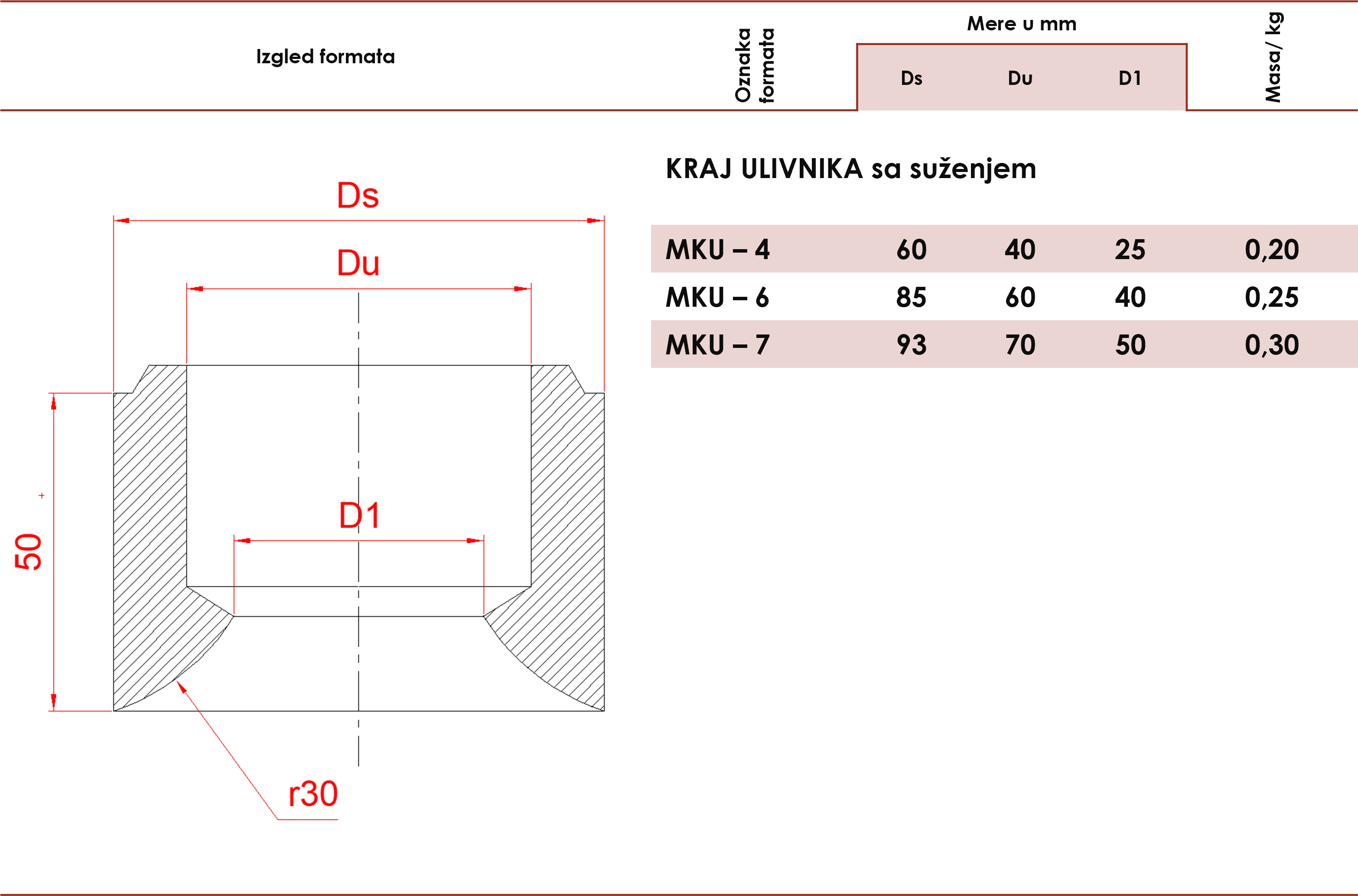

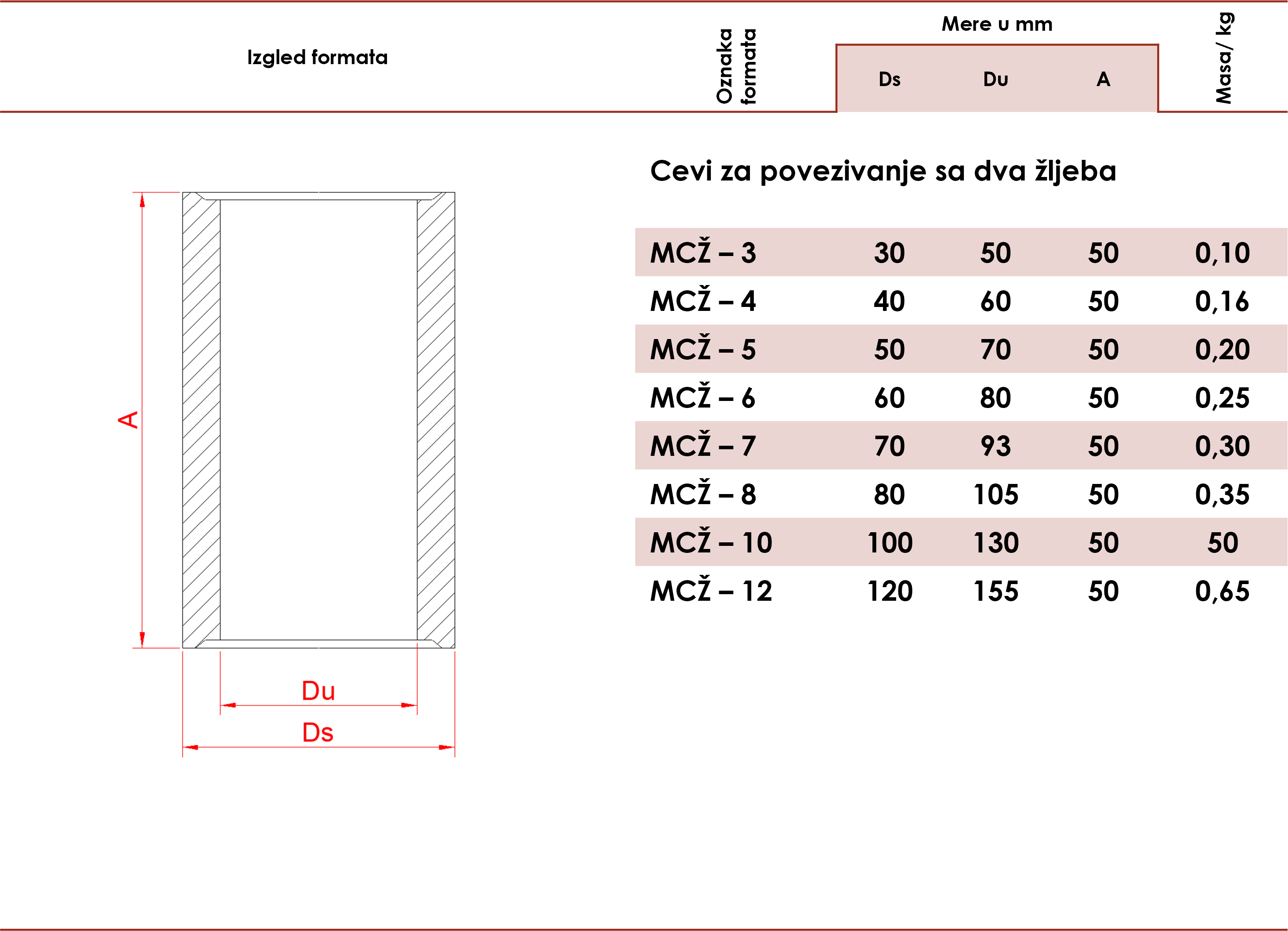

NOTE: Dužina cevi po narudžbi potrošača može biti od 50 – 255mm. Prva cifra iza slovne oznake označava:

0 – bez žljeba i pera,

1 – sa žljebom,

2 – sa perom,

3 – sa perom za MKO i MKZ

BDV REFRACTORY is the successor of "Keramika-Gavrilović" , which has been present on the market since 1993 as a producer of technical ceramics. In an area rich in deposits of refractory clays, where the industry of refractory materials has developed, by expanding capacity we have completed the production program with fireclay bricks of standard and special formats, as well as refractory concrete and masses for the needs of non-ferrous and ferrous metallurgy, foundries, brickworks, sugar factories, oil factories, thermal power plant…

Developed by 2A Design